retort food makers

Retort food packaging makers produce versatile packages that are made of several layers of plastic or steel aluminum foils. These pouches are suitable for refining foods such as meat, cheese, as well as also soups. They are very easy to open up as well as take care of.

The development of the antiphon product packaging sector is sustained by expanding need for lightweight as well as compact product packaging. In addition, consumers are likewise seeking fresh choices, which is driving antiphon packaging producers to develop new products.

Antiphon product packaging is an alternate to traditional commercial canning techniques. It supplies an perfect service for makers who intend to maintain the sterility of their food products during circulation. Additionally, antiphon bags evaluate significantly less than canisters. This suggests that they call for significantly much less storage area, allowing the procedure of retorting to be completed in a shorter time.

In the last few years, antiphon pouches have actually become much more different. These plans are currently used for processed foods along with for ready-to-eat dishes. As an example, makers use them for soups, instant noodles, and also pre-cooked dinner items.

Antiphon product packaging is presently the biggest thermal food handling process. It is created to maintain the high quality of the item, utilizing the fastest feasible home heating time. Since the heat direct exposure is lowered, nutrition losses are minimized. Additionally, the preference as well as flavour are boosted.

retort food processing

Antiphon food product packaging is an reliable method to maintain food. It raises the sturdiness and also service life of the plan, while minimizing the storage area. Furthermore, the pouches are simple to open up as well as manage.

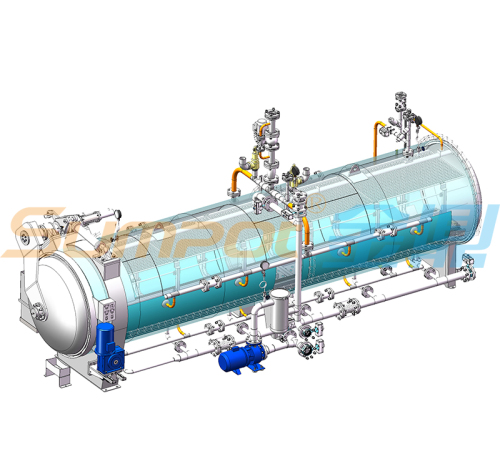

Retorts are commonly used in the food and beverage industry. They are ideal for shelf stable items. Since retort cooker are small and light-weight, they are a fantastic alternate to cans.

A antiphon food product packaging process entails heating the food. This warm is generated by utilizing superheated water. The hot water is recirculated through a warm exchanger to cool the container.

After the antiphon procedure is full, the food products are kept in suitable cartons. These containers assist in transport as well as screen in grocery stores.

Some retort modern technology systems likewise use steam for food preparation. When a food pack with a pressure-sensitive valve opens, it permits the launch of heavy steam. The warm water in the storage tank is re-heated to the wanted sterilization temperature and also returned to the storage tank for the next treatment.

Retorts were first established in the 1950s. Ever since, the innovation has progressed, and also antiphons have actually come to be a lot more different. Today, antiphons are used for many different purposes, including post-fill thermal handling of canned foods and also to preserve sterility throughout circulation.

food autoclave

Antiphon product packaging for food has actually been used in the food industry for years. It is an reliable thermal processing technique that supplies risk-free rack security and also commercially sterilized filled plans.

A antiphon is a shut vessel that uses vapor under pressure to sanitize foods. Food are positioned in the pack, and also the retort is then heated to the preferred temperature level and also stress. This procedure kills dangerous microorganisms and also spores inside the food.

Food retorts are available in several formats, including metal containers, glass containers, and also trays. Each package style has its very own advantages and downsides. The most typical package framework for thermally clean and sterile low-acid foods is the cylindrical metal can. Nonetheless, a number of other bundle frameworks have actually been created.

One of the first retorts utilized for thermally sterilized low-acid food was the fixed vapor retort. Throughout the very early 1970s, a foil-free retortable pouch was presented to pack meat dumplings.

Various other packaging layouts have actually arised in the past years. These include retort bags and also adaptable plastic or aluminium trays. One of the most usual retort pouches feature three or 4 layers of materials. Each layer has a different impact on the item's shelf life.

The use of a multi-layer retort bag is beneficial because it is versatile as well as heat-sealable. They are made from heat-resistant plastics and also have leak resistance. canning line can also be recycled right into aluminized material.