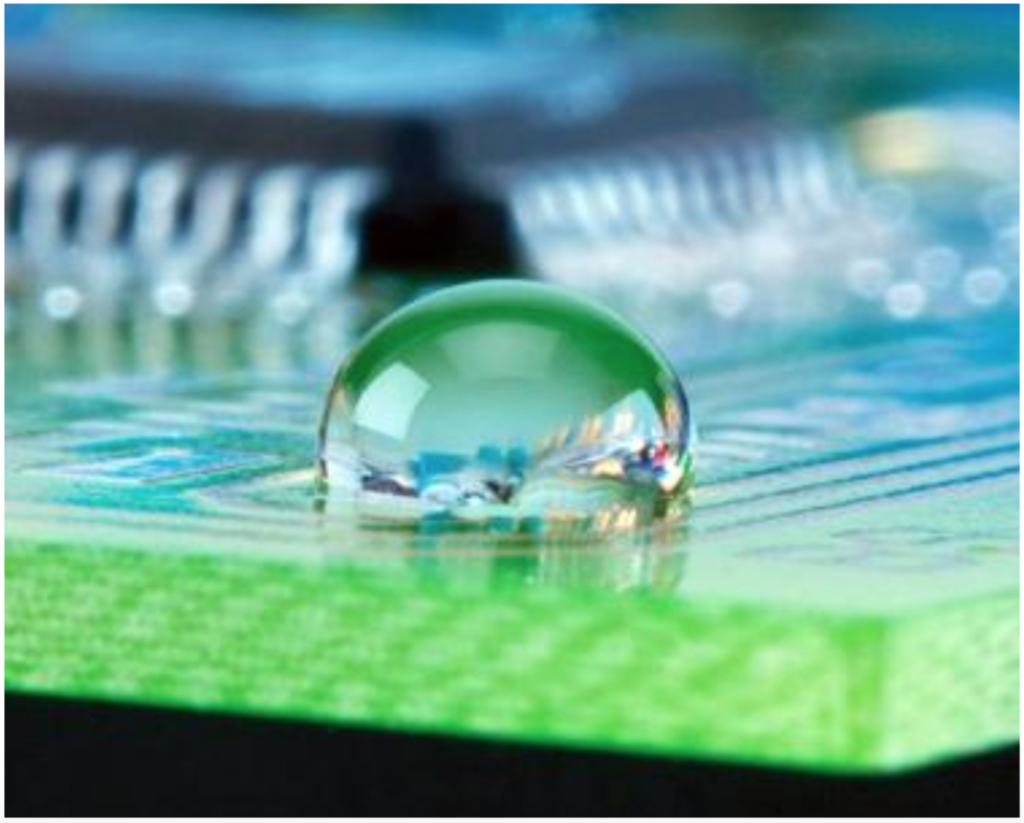

Hydrophilic Coating for Healthcare Devices

A hydrophilic coating is the material that will be used on a variety of medical devices. It assists protect them coming from corrosion and corrosion. This type of coating will be usually applied to alloys and plastics, yet it can also be put on glass and ceramics.

medical device coatings

Hydrophilic medical device coatings are a great approach to protect patients from infections in the hospital. The coatings can be used to numerous professional medical devices, for instance catheters, blood pressure displays, and stents. They might also improve typically the lubricity of a new device, that can increase the ease of insertion.

Hydroxyl (OH) coatings, primarily hyaluronic acid, are used to reduce prospective trauma during invasive procedures. Typically, polymers are selected based on their mechanical attributes and surface chemistry.

These technologies let doctors to very easily access urological systems. Additionally, they help in order to minimize the danger of trauma throughout vascular and brain procedures. Currently, scrubbing reducing coatings are used to reduce the risk of destruction to the walls of blood veins.

Among the nearly all common products that use coatings to lower friction include catheters, guidewires, stents, and even bioabsorbable scaffolds. Various players are creating novel protective clinical coatings.

In addition, an evergrowing awareness associated with the benefits of hydrophilic coatings has led to the introduction of new devices with one of these materials. However, these coatings are also vunerable to mechanical abrasion, which in turn causes stress in the chemical binds. This can result in the development involving suboptimal performance.

As a result, presently there is a dependence on medical device coating s to be created by qualified firms which might be capable of minimizing the potential risks associated along with this type of technology. It is important for typically the manufacturer to have got stringent quality command measures in place.

clinical device layer

Hydrophilic medical device coatings provide clean lubricity on health care devices that contact human tissue. This lubricity reduces chaffing, which may avoid wear and split. It also defends medical devices coming from microbial growth.

Many medical devices are now being manufactured using hydrophilic coatings. These include drug-eluting coatings of which slow the launching of drugs in order to blockages.

Antimicrobial coatings are also increasing popularity. They can be used to prevent bacterial colonization on the surfaces of memory foam implants. However, they will are costly and even may not be cost effective for several medical device companies.

Developing an advanced medical device coating entails several complex procedures. Some companies, this kind of as Biocoat Incorporation., use naturally occurring substances, such seeing that hyaluronic acid, in order to develop their films. Other companies, such as Formacoat, specialize in coatings which can be engineered for specific application needs.

A global market for hydrophilic medical device coatings is approximated to grow from a CAGR involving 5. 81% by 2016 to 2023. In terms of revenue, North America is the greatest market. Europe will be the second largest marketplace. Asia Pacific could be the fastest growing place. Over the predict period, the market place is projected in order to reach USD 10, 109. 7 , 000, 000.

Several key participants are identified in the market. Each company is evaluated on the production capacity, item portfolio, and local presence. Increasing foreign investment in typically the medical equipment market is expected to be able to boost the demand for medical device coatings.

hydrophilic finish medical device

Hydrophilic coatings are utilized over a variety regarding medical devices. They provide a quantity of benefits in order to the user, together with a reduction in scrubbing plus a smoother surface area. A hydrophilic covering can also provide a system to the delivery associated with antibiotics, antimicrobials, or perhaps other active pharmaceutical ingredients.

Although antimicrobial coatings for medical devices have been around for many years, they have got only lately become commonplace on the subject of a variety of health care devices. This is certainly largely because of the fast speed from which producing technology has superior.

The advantages associated with by using a hydrophilic finish on a device can range from lowered friction to increased biocompatibility. These advantages can make a new device easier to be able to use and less more likely to cause affected person discomfort. However, incorporating a hydrophilic layer inside the design course of action can be quite a challenging activity.

You should select a new vendor together with the suitable qualifications to perform the coating process. The selection process must start at the original stage in typically the development process. Looking for the right supplier may help ensure that will the product will be developed properly and will meet internal plus external requirements.

Typically the selection process needs to be based on crucial criteria, including the particular type of app, the amount involving the device to become coated, and the particular cost. Questions ought to be provided to the quality systems, gear, and processes included.